Title is a joke.

I want to discuss first how the Swords are graded. It's a break week and nothing really important in the chapter to discuss.

That's the art of Katana Making and Why supreme grade swords are so fuckin Rare.

- It's Simply Beautiful on how much if attention to detail Oda has given to swords and it's "Hammon" pattern.

- Also those who are Wondering why Hammon are not similar in every sword. , it's because of different School use their own Secret of crafting the weapon, from altering Clay content to temperature of Water.

- Ichimonji School , Kotetsu School , And many other school had their own way of Crafting a sword. And most swords in supreme grade/very good grade sword list are from this school.

- You can see many patterns here from

I want to discuss first how the Swords are graded. It's a break week and nothing really important in the chapter to discuss.

How Swords are Graded in ranking systems.

wazamono swordsmiths, grouped into four "grades" based on the cutting performance of their blades.

Blackblade*** - This is fictional , no black blade exists in real life. But that's what portrayal of blackblade is all about , " Unbreakable ".

| Grade | Count | Performance (Out of ten) |

|---|---|---|

| Black Blade*** | 2 | 10 Times |

| Supreme Grade Sword | 12 | 8-9 Times |

| Excellent Grade Sword | 21 | 7-8 Times |

| Very Good Grade Sword | 50 | 5-7 Times |

| Good Grade | 80 | 3-4 Times |

Blackblade*** - This is fictional , no black blade exists in real life. But that's what portrayal of blackblade is all about , " Unbreakable ".

Now Why are there so less amount of Supreme Grade Swords.

For that I would like explain the Process of Forging a Katana.

The process is called " Tatara "

- the process has been unchanged for years ,

- Only known changes made are , Human Effort of labour of keeping furnance on for hours and Hammering , rest is same from the past 1300 years.

- Almost 600 Kgs of Charcoal is used Increase the temperature upto 1300°C. And All impurities such as Sulphur , Phosphorus and Silicon who have Comparatively lower Metling point just melts and come out as "Slag".

- Now 600 kgs of " Iron Sand " which is considered to have the highest concentration of iron is used.

- Iron at it's purest form is soft which is very unlikely for a sword. Hence only Iron is not used in the Sword.

- Rather an Alloy is used called " Steel " , which has high concentration of Iron and Carbon. All the charcoal burnt away and Carbon attached to purest iron.

- Gives us only " 10~Kg " of Block.

- Steel vs Iron when Applied force.

Step 1 :

- Smelting of Iron Sand and Charcoal.

- Slag is removed.

- In the end we get a mass of Steel which has Different Grades. Means the Quality of Steel.

Step - 2

- The block of Steel he sent out to 300 Swordsmiths in the country and only 30 of them do this as a full time job.

-

- All of them are given only a Block of steel , around a kg or two.

- All of them are given only a Block of steel , around a kg or two.

- Then they beat it with Hammer and flat it until it looks like this.

- Now you might be wondering what's the point of Beating it flat and Folding it into same Block of Steel again?

- Now you might be wondering what's the point of Beating it flat and Folding it into same Block of Steel again?

- This ensure that all the impurities and Carbon atom which is distributed unevenly in the block of steel , Get flatened and get folded over to make a uniform consistencies of Carbon around the blade , which would ensure toughness through out the sword.

- If carbon concentration is less in some area of Sword , The sword would be weaker at that point. And strong at different at some point. Which would make the more breakable on impact which is definitely not what a swordsman want in middle of a battle.

- So the sword is folded out many times to Ensure uniform distribution of Carbon in the sword.

- A block is folded around 10-15 times in modern day.

- A block is folded around 10-15 times in modern day.

- and Some blade reaching upto 30 Folds.

And folding in presence of Oxygen , Make oxidation take place and give us beautiful pattern called " Hammon ".

- Some Swords have fuckin 30 folds which gives us over 1 Billion fold patterns.

- Some Swords have fuckin 30 folds which gives us over 1 Billion fold patterns.

- Though Modern day only 10-15 folds are made which I would Explain below why.

- Though Modern day only 10-15 folds are made which I would Explain below why.

Step 3

- after this sword is beaten into long Straight Sword. And Covered with Clay on part of sword.

- Both part - Main sharp edge and other being Maine body of the sword.

- Sharp edge gets , thin layer of Clay in it and and Main spine gets thick layer of Clay.

Now the blade is heated Again.

Now the blade is heated Again.

- the carbon from Clay , gets inside the blade , and As this is very important , step , because After this a process called " Quenching " take place.

- Where it's cooled very rapidly.

- what it does ? The carbon atom in thick side of the blade , Starts to shift or stick to sharp side of the Blade leaving the Spine of the Blade and going to sharp edge of the blade. As thick layer of Clay was applied on this side , The cooling is slower compared to Thin clay covered side of the sword.

- why does it matter? As I said previously,

Carbon atom of different quantity changes the composition of Iron and turn into harder and harder steel. But in turn it makes it brittle and more often breaks then bend.

- spine which has lower content of Carbon atoms , Bends , rather than break.

- as Carbon tries to get out of the system as it is cooled very quick , The blade expands.

- sharp edges which has the higher content of carbon gets expanded more and Main spine stays intact which gives us the legendary samurai curve Katana.

- now spine part which has less amount of carbon atom is called "Ferrite"

- sharp edge which has higher concentration of carbon atom is called " Cementite ".

- and both of them together is called " perlite "

- Extreme edges which has the highest content of Carbon is called " Marcentite " . This one expands the most and is the hardest compound of Katana , but also the most brittle substance of Katana , easier to chip away as more impact is applied but at the same time strongest and sharpest.

- Extreme edges which has the highest content of Carbon is called " Marcentite " . This one expands the most and is the hardest compound of Katana , but also the most brittle substance of Katana , easier to chip away as more impact is applied but at the same time strongest and sharpest.

- Different carbon content gives different color to the sword which you can see above.

- Now the most neat part is , after all this Hardwork , the quenching process is like , you throw the sword in water for cooling. And pray to the stars , that expansion of Carbon doesn't break the sword or blast the sword.

- only 1 out of 3 swords survives this. And greater the amount of folds you make greater becomes the chances of Sword bursting or breaking into two.

- The final Composition of sword looks like this and thus given a " Grade ".

- which is why we have so less amount of " Supreme Grade sword ".

- which is why we have so less amount of " Supreme Grade sword ".

- Most of the attempt of making Supreme grades fails as it contains more and more Folds which boils down to more uniform carbon placement and burst into pieces when cooled immediately only a few survives and becomes the best in class swords.

- the occurance of it is so low that an sword of 1600s , supreme grade sword was sold at 105 million dollars.

The process is called " Tatara "

- the process has been unchanged for years ,

- Only known changes made are , Human Effort of labour of keeping furnance on for hours and Hammering , rest is same from the past 1300 years.

- Almost 600 Kgs of Charcoal is used Increase the temperature upto 1300°C. And All impurities such as Sulphur , Phosphorus and Silicon who have Comparatively lower Metling point just melts and come out as "Slag".

- Now 600 kgs of " Iron Sand " which is considered to have the highest concentration of iron is used.

- Iron at it's purest form is soft which is very unlikely for a sword. Hence only Iron is not used in the Sword.

- Rather an Alloy is used called " Steel " , which has high concentration of Iron and Carbon. All the charcoal burnt away and Carbon attached to purest iron.

- Gives us only " 10~Kg " of Block.

- Steel vs Iron when Applied force.

Step 1 :

- Smelting of Iron Sand and Charcoal.

- Slag is removed.

- In the end we get a mass of Steel which has Different Grades. Means the Quality of Steel.

Step - 2

- The block of Steel he sent out to 300 Swordsmiths in the country and only 30 of them do this as a full time job.

-

- Then they beat it with Hammer and flat it until it looks like this.

- This ensure that all the impurities and Carbon atom which is distributed unevenly in the block of steel , Get flatened and get folded over to make a uniform consistencies of Carbon around the blade , which would ensure toughness through out the sword.

- If carbon concentration is less in some area of Sword , The sword would be weaker at that point. And strong at different at some point. Which would make the more breakable on impact which is definitely not what a swordsman want in middle of a battle.

- So the sword is folded out many times to Ensure uniform distribution of Carbon in the sword.

- and Some blade reaching upto 30 Folds.

And folding in presence of Oxygen , Make oxidation take place and give us beautiful pattern called " Hammon ".

Step 3

- after this sword is beaten into long Straight Sword. And Covered with Clay on part of sword.

- Both part - Main sharp edge and other being Maine body of the sword.

- Sharp edge gets , thin layer of Clay in it and and Main spine gets thick layer of Clay.

- the carbon from Clay , gets inside the blade , and As this is very important , step , because After this a process called " Quenching " take place.

- Where it's cooled very rapidly.

- what it does ? The carbon atom in thick side of the blade , Starts to shift or stick to sharp side of the Blade leaving the Spine of the Blade and going to sharp edge of the blade. As thick layer of Clay was applied on this side , The cooling is slower compared to Thin clay covered side of the sword.

- why does it matter? As I said previously,

Carbon atom of different quantity changes the composition of Iron and turn into harder and harder steel. But in turn it makes it brittle and more often breaks then bend.

- spine which has lower content of Carbon atoms , Bends , rather than break.

- as Carbon tries to get out of the system as it is cooled very quick , The blade expands.

- sharp edges which has the higher content of carbon gets expanded more and Main spine stays intact which gives us the legendary samurai curve Katana.

- now spine part which has less amount of carbon atom is called "Ferrite"

- sharp edge which has higher concentration of carbon atom is called " Cementite ".

- and both of them together is called " perlite "

- Different carbon content gives different color to the sword which you can see above.

- Now the most neat part is , after all this Hardwork , the quenching process is like , you throw the sword in water for cooling. And pray to the stars , that expansion of Carbon doesn't break the sword or blast the sword.

- only 1 out of 3 swords survives this. And greater the amount of folds you make greater becomes the chances of Sword bursting or breaking into two.

- The final Composition of sword looks like this and thus given a " Grade ".

- Most of the attempt of making Supreme grades fails as it contains more and more Folds which boils down to more uniform carbon placement and burst into pieces when cooled immediately only a few survives and becomes the best in class swords.

- the occurance of it is so low that an sword of 1600s , supreme grade sword was sold at 105 million dollars.

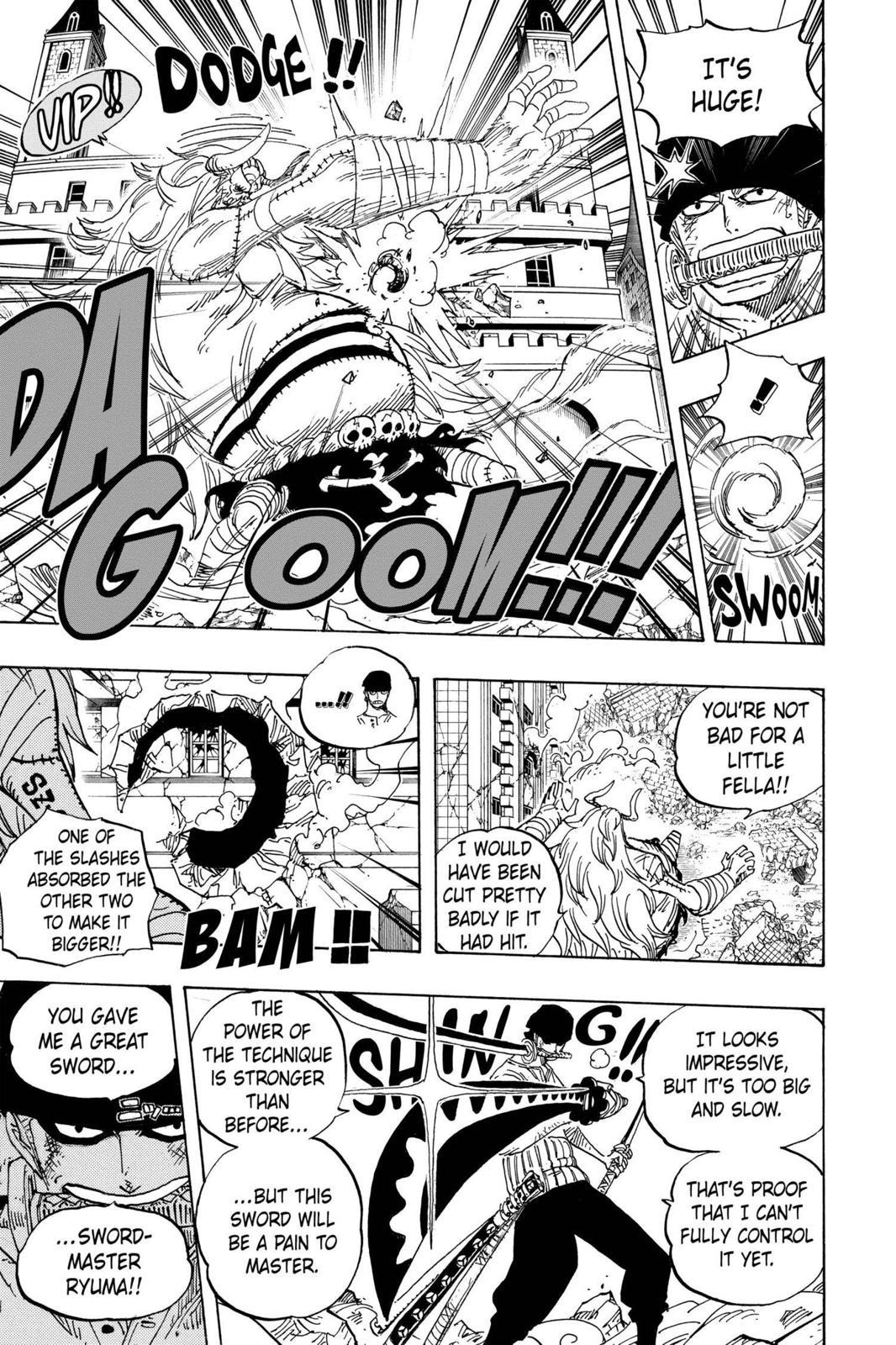

If we are done with this let's Shed on light on Katana's in One piece.

- i never Thought patterns could mean that much. - It's Simply Beautiful on how much if attention to detail Oda has given to swords and it's "Hammon" pattern.

- Also those who are Wondering why Hammon are not similar in every sword. , it's because of different School use their own Secret of crafting the weapon, from altering Clay content to temperature of Water.

- Ichimonji School , Kotetsu School , And many other school had their own way of Crafting a sword. And most swords in supreme grade/very good grade sword list are from this school.

- You can see many patterns here from

- Horseteeth like Hammon in Shisui

- Flame type Hammon in Enma

- Waves /Flame type pattern in Kitetsu line

- Plain hammon in Wado Ichimonji